Light Rail Inspections

Light Rail Inspections

RTD conducts regular inspections of its entire light rail system. The intent of inspections is to identify preventive maintenance that may need to be addressed in the near-term or future. This proactive approach allows the agency to ensure all rail assets are in a state of good repair and avoid long-term service disruptions and major infrastructure issues.

RTD adheres to the American Public Transportation Association (APTA) standards for the periodic inspection and maintenance of fixed structure rail transit tracks. APTA’s standards, which RTD began using in May 2024, include visual, electrical, and mechanical inspections of components that affect safe and reliable operations, as well as standards for implementing corresponding speed restrictions. These standards also identify the necessary qualifications for rail transit system employees or contractors who perform periodic inspections and maintenance tasks. Regular inspections support and greatly reduce the risk of hazards and system failures.

Inspection Timelines

RTD schedules and conducts regular inspections of its entire light rail system to proactively manage assets and plan for large-scale renewal and reconstruction efforts. Inspections are conducted by trained staff annually, quarterly, monthly, and twice weekly, depending on the type of inspection being performed.

Annually

Once a year, RTD conducts an ultrasonic inspection of all 120 miles of track.

Quarterly

Staff walk the entire system every 90 days to take additional measurements and carefully document anomalies. The quarterly walking inspections allow the agency to take measurements, collect thousands of data points, identify recurring issues, and analyze patterns. The actual month of an inspection may be adjusted within a quarter.

| Corridor | Line(s) | Months |

|---|---|---|

| Central Corridor | D, H, and L | January, April, July, and October |

| Central Platte Valley Corridor | E and W | February, May, August, and November |

| Parker Road / I-225 Corridor | H and R | March, June, September, and December |

| Southeast Corridor | E, H, and R | February, May, August, and November |

| Southwest Corridor | D | March, June, September, and December |

| West Corridor | W | January, April, July, and October |

Monthly

Turnout inspections are conducted monthly.

Twice Weekly

Staff use a hi-rail (hy-rail) vehicle to inspect all corridors and rail alignments twice weekly at speeds where the track can be carefully assessed. Hi-rail vehicles travel at a speed no greater than 5 MPH when inspecting at-grade crossings and switches, and up to 15 MPH elsewhere on the system. These vehicle speeds allow staff to effectively perform track inspections.

3.1 Track Inspection

a. Tracks used by revenue trains shall be inspected weekly on foot, or by riding over the track in a vehicle at a speed that allows detection of noncompliance with these standards.

(APTA Rail Transit Track Inspection and Maintenance, page 2)

Frequently Asked Questions

What prompted the Southeast Corridor’s inspections in May 2024?

Track inspections are conducted every 90 days, and the Southeast Corridor was due to be inspected at that time.

Will RTD wait until all repairs are completed before lifting any of the speed restrictions?

No. Speed restrictions will continue to be lifted in the slowdown zones as repair work is completed.

Did RTD expect to find issues before the inspections were conducted in May 2024?

No. Prior to conducting the May 2024 inspections, RTD did not anticipate that preventive maintenance issues would be discovered and lead to speed restrictions.

Inspections are conducted to inform the agency about preventive maintenance that may need to be addressed in the future or issues that currently exist. The Southeast Corridor inspections conducted in May 2024 were done to provide RTD with information about its assets, and the track was due to be inspected at that time.

All transit agencies conduct regular inspections to discover preventive maintenance issues and defects. By addressing issues and defects through early intervention efforts and maintenance, RTD is able to ensure all rail assets are in a state of good repair. Preventive maintenance supports RTD’s efforts to avoid larger disruptions and major infrastructure problems.

What are enhanced inspections?

Beginning in May 2024, RTD began using an enhanced inspection methodology. Enhanced inspections include a more in-depth, regular assessment of the entire rail system and its infrastructure. Under this enhanced process, RTD now conducts 25 rail inspections each quarter as opposed to four previously. The enhanced inspections improve RTD’s ability to proactively manage its assets and plan for large-scale renewal and reconstruction efforts.

Specifically, trained staff use a hi-rail (hy-rail) vehicle to ride the entire system twice weekly at speeds where the track can be carefully inspected. In accordance with Section 3.1 of the American Public Transportation Association (APTA)’s rail inspection standards (APTA RT-FS-S-002-02, Rev. 1) tracks “must be inspected weekly on foot, or by riding over the track in a vehicle at a speed that allows detection of noncompliance with [APTA’s] standards (see page 2).” The hi-rail vehicles travel at a speed no greater than 5 miles-per-hour when inspecting at-grade crossings and switches, and up to 15 miles-per-hour elsewhere on the system. These vehicle speeds allow staff to effectively perform track inspections. Additionally, staff walk the entire system every 90 days to take additional measurements and carefully document anomalies.

As part of the enhanced inspections, RTD has also improved its record-keeping process. Maintaining more robust records and comprehensive documents allows the agency to identify recurring issues, analyze patterns, take measurements over time, and discover trends across the entire rail system. It also ensures there is consistency in the inspection process and enhances transparency with stakeholders, customers, and the community.

Why is it important for RTD to maintain its assets in a state of good repair?

In 2023, RTD launched the strategic initiative of Back to Basics, a priority emphasis on maintainingall of the agency’s assets in a state of good repair. Like other mass transit agencies, RTD’s assets are at varying ages within their useful life.

All of RTD’s fixed assets are regularly monitored and inspected to ensure they support operationally safe, accessible, and dependable services. Regular inspections guarantee that the public’s previous investments in the system remain intact and are required by regulatory oversight entities. Inspections are also a critical component of effective rail management, contributing to the safe, reliable, and efficient operation of RTD’s rail system.

What are RTD’s standards for track inspection and maintenance?

The American Public Transportation Association (APTA) has established standards for the periodic inspection and maintenance of fixed structure rail transit tracks. APTA’s standards include periodic visual, electrical, and mechanical inspections of components that affect safe and reliable operations. This standards also identify the necessary qualifications for rail transit system employees or contractors who perform periodic inspection and maintenance tasks.

RTD began using APTA’s standards (APTA RT-FS-S-002-02, Rev. 1) in May 2024. The standards guide staff in assessing and verifying that RTD’s tracks are operating safely and as designed. The standards also support the rail network’s reliability by noting preventive maintenance, and it greatly reduces the risk of hazards and failures.

As outlined on page 20 of APTA’s standards, the current 10 mile-per-hour speed restrictions follow the minimum remedial actions. Depending on the size of the railhead burn, which is referred to as “wheel burn” in Table 11c, the minimum remedial action required is reduced speeds until the issue is addressed. Depth and size measurements have been taken for each instance of railhead burn along the Southeast Corridor.

What standards did RTD use prior to adopting APTA’s requirements for inspections and maintenance?

Prior to adopting APTA’s standards, RTD conducted inspections using an internally developed process that included less frequent inspections.

Are additional inspections planned across other light rail corridors?

Yes. RTD will continue to conduct regular inspections of the entire light rail system and track infrastructure. Inspections are conducted with regular frequency by trained staff. The agency’s more than 120 miles of light rail track is inspected every 90 days. If warranted, speed restrictions are put into place following inspections until maintenance issues are resolved.

Is rail grinding an option for some of the instances of railhead burn that do not yet meet the depth and size requirements for replacing the rail?

Yes. In accordance with APTA’s standards, rail grinding is an option for some of the instances of railhead burn along the Southeast Corridor. This remedial action will be taken when and where it is warranted.

Do the recent inspections relate to RTD’s 19th and Stout Street corrective action plan?

In 2022, RTD self-reported to the Colorado Public Utilities Commission (PUC) that the rail conditions at the intersection of 19th and Stout streets were found to be below industry acceptable standards for normal rail activities. The PUC approved RTD’s proposed corrective action plan outlining steps the agency will take in the future to ensure its light rail track is inspected and maintained at the highest industry standards. The recent inspections were conducted consistent with RTD’s corrective action plan measures, which include speed restrictions when issues are discovered.

Southeast Corridor’s Inspection Findings

A number of minor issues and cosmetic defects were discovered during RTD’s recent track inspection. The Southeast Corridor’s light rail track remains safe for operations under the current speed restrictions. No structural defects to the rail base, fasteners, rail substructure, or rail bed were observed. RTD has every indication that the track remains stable and intact along the Southeast Corridor.

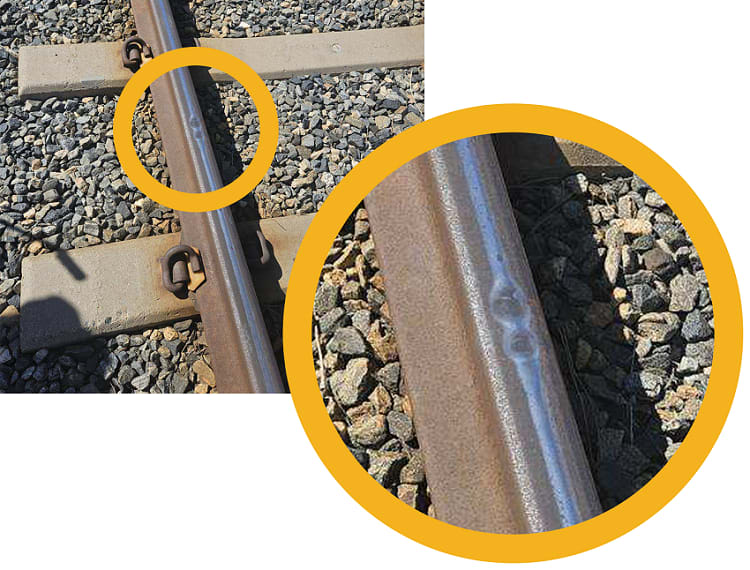

The May 2024 inspections found instances of railhead burn, which is a surface defect on the top side of the track where light rail vehicle wheels make contact with the rail.

Photo: Railhead burn found on a section of the Southeast Corridor’s light rail track (May 2024)

What is railhead burn?

Railhead burn refers to damage on the top surface of a rail, which is known as the railhead. It isprimarily caused by wheel friction and leads to the formation of tiny cracks and surface irregularities. Over time, this damage can affect the smoothness of the rail, potentially compromising safety and requiring maintenance or rail replacement.

Why do railhead burns require trains to operate at slower-than-normal speeds?

RTD always adheres to the highest level of safety standards, even when it results in an impact to scheduled services and on-time performance. If railhead burns are not adequately addressed and the track maintained, the issue has the potential to cause cracks. Trains operate at slower-than-normal speeds to ensure customers and employees remain safe until maintenance is completed. The Southeast Corridor’s light rail track remains safe for operations under the current speed restrictions.

Additionally, examples of the track ballast needing to be leveled or improved were observed. Ballast is a crushed stone or gravel material that is used to support and level tracks in a railbed. The primary purpose of ballast is to provide stability to the tracks, allowing trains to run smoothly and safely.

Photo: Insufficient amount of ballast found on a section of the Southeast Corridor’s light rail track (May 2024)